- Production

- Parts and assembly units

- Gear wheels

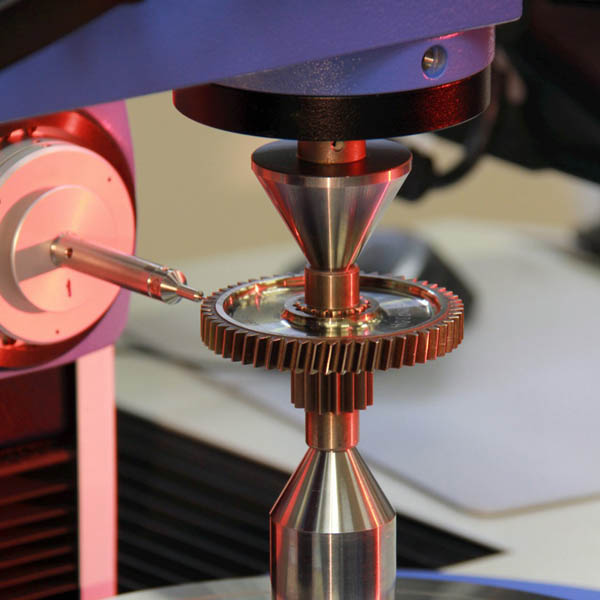

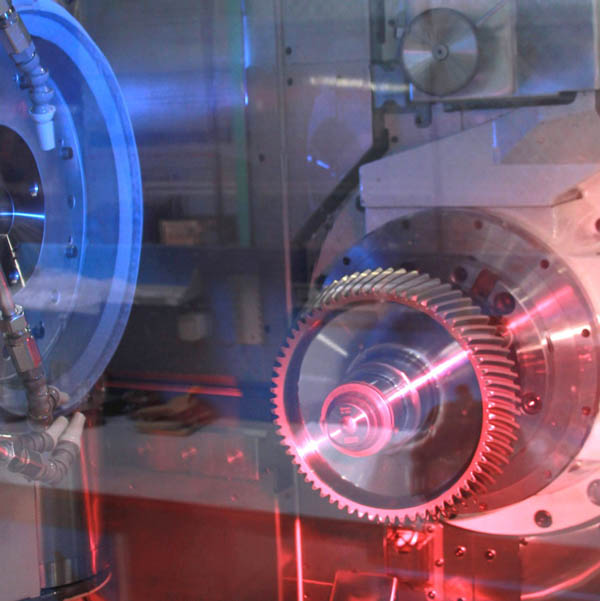

Gear wheels

Over 400 types of gear wheels and splined springs with outer diameters from 12 to 600 mm and a module from 1 to 7.75 are manufactured commercially. Gear wheel types: cylindrical wheels with outer engagement and straight and helical teeth, cylindrical wheels with inner engagement, tapered wheels with straight and helical teeth.

Machining methods: lathing, grinding, gear cutting, milling, gear-tooth shaping, gear-tooth grinding, milling, honed finishing, gear shaping, spline grinding, electrosparking and broaching machining. Various kinds of mechanical surface hardening and a variety of chemical and thermal treatment methods, in particular nitride hardening, cement grouting, die quenching, are applied. Most parts pass dynamic balancing.

| Gear wheels | |

| Accuracy degree | up to 5-4-4 |

| Module, mm | 1,5 …. 7,75 |

| Number of gear teeth | 6 …. 154 |

| Overall dimensions, mm | 18 …. 715 |

| Weight, kg | 0,02 …. 51,00 |

| Tapered wheels with circle-arc teeth | |

| Number of pairs | 22 |

| Front-end module, mm | 3 …. 7,75 |

| Axial angle | 27,5° …. 136° |

| Accuracy degree, class | 6 |