- Production

- Parts and assembly units

- Non-rotational parts

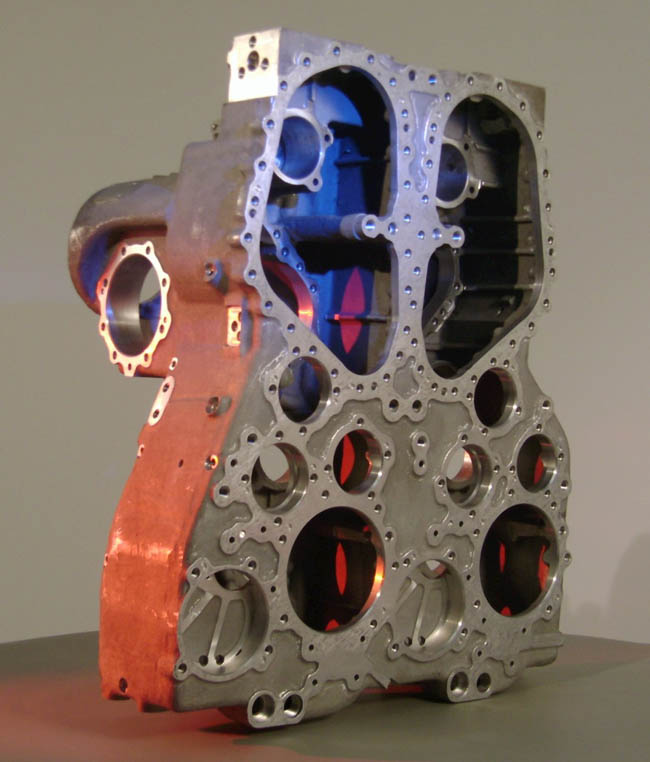

Non-rotational parts

The enterprise manufactures over 500 non-rotational parts with a wide range of overall dimensions from 15 to 1300 mm.

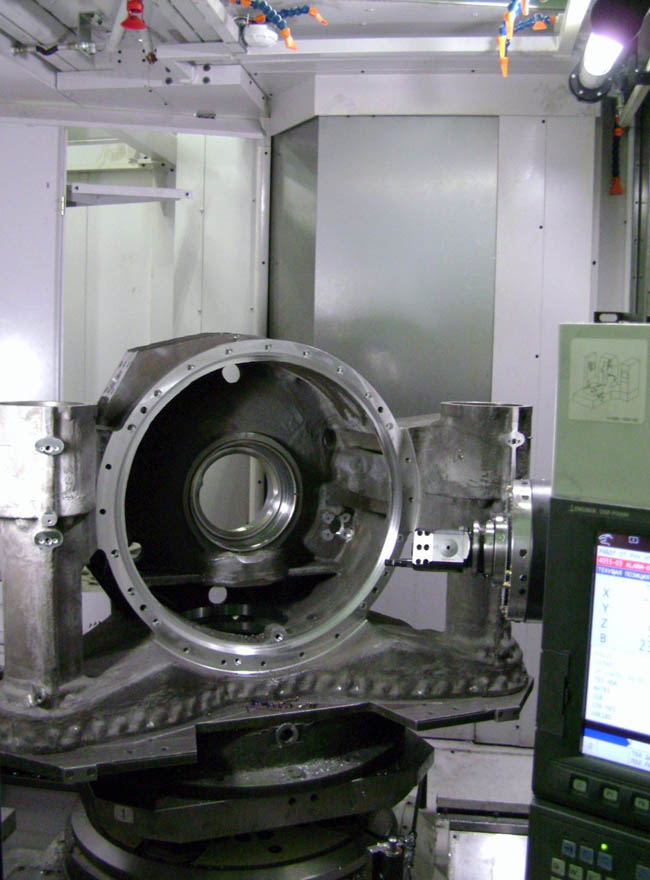

Large-size casings made of magnesium alloys have complex geometry and fall under high strength requirement parameters. Their manufacture includes:

- treating in specialized temperature-controlled sections,

- many measurements on coordinate inspection machines – up to 5000 parameters per 1 casing,

- extensive use of CNC-based machining centres – up to 2500 adjustments of cutting tools,

- applying special protective galvanic and paint coatings,

- many hydraulic and pneumatic tests.

| Overall dimensions, mm | 15 …. 1300 |

| Weight, kg | 0,02 …. 180 |

| Tolerance for coordinate dimensions (large-size casings), µm | up to 20 |

| Surface finish of mounting seats | up to Ra 1,6 |

| Material: Steels, titanium, aluminum and magnesium alloys | |

| Workpieces: CP castings, large-size shaped castings, die-casting, closed die-forging | |